TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

Jul . 31, 2025 06:40

Back to list

Kitchen Glasses: Premium Anti-Fog & Splash Protection

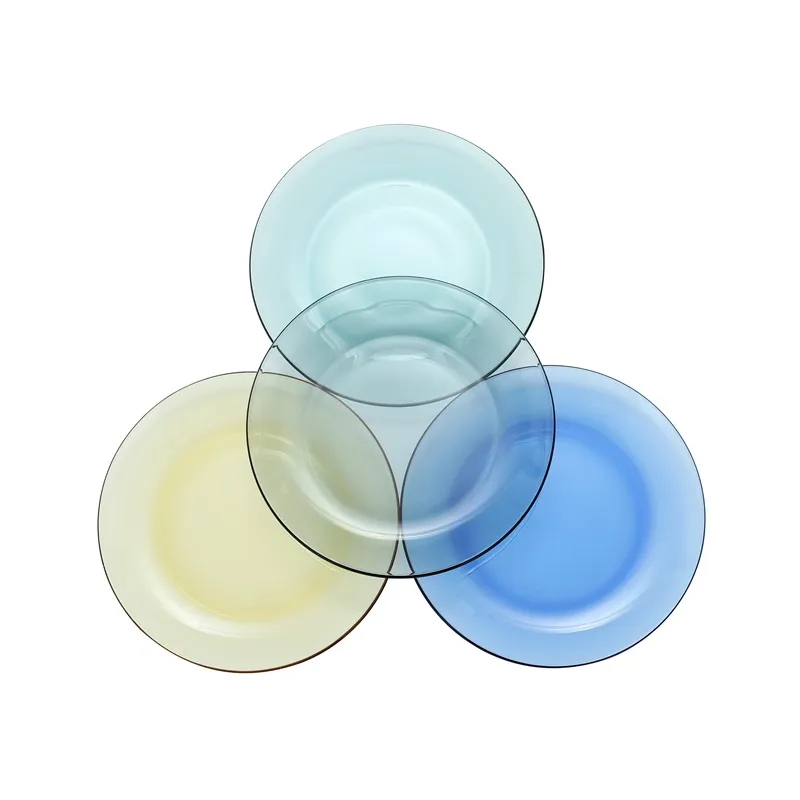

Kitchen Glasses: Industry Trends, Technical Comparison, and Application of 9 Inch 10 Inch Stained High Borosilicate Glass Plate

The kitchen glassware industry has entered an era of high performance and sustainability. From traditional soda-lime glass to advanced high borosilicate products, kitchen glasses now cater to safety, aesthetics, durability, and multifunctional needs in both domestic and industrial culinary environments. This comprehensive guide investigates product specifications, production methodology, competitive landscape, and the real-world advantages of kitchen glasses, focusing on the 9 Inch 10 Inch Stained High Borosilicate Glass Plate.

Industry Overview & Evolving Trends

According to the Glass Packaging Institute (GPI), global glassware demand in the kitchen sector will reach USD 8.5 billion by 2028, registering a CAGR of 4.7% from 2022 onward (source). Major trends include:

- Shift to high-borosilicate glass for superior thermal & chemical resistance.

- Rising custom-decorated glassware matching kitchen aesthetics.

- Strict compliance with hygiene (FDA, ISO 9001) & safety (ANSI Z97.1) standards.

- Integration of multifunctional features (oven-safe, dishwasher-safe, etc.).

Typical Kitchen Glasses Parameters: Market Overview

| Type | Material | Thermal Resistance | Impact Strength | Transparency | Certification | Applications |

|---|---|---|---|---|---|---|

| Soda-lime Glass | Soda, Silica, Lime | Up to 150°C | Medium | 92% | FDA | Cups, plates, jars |

| Toughened Glass | Soda-lime (tempered) | Up to 200°C | High | 91% | EN 1183 | Cookware, covers |

| High Borosilicate Glass | Boron, Silica, Soda | Up to 500°C | Very High | 93% | ISO 9001, ANSI Z97.1, FDA | Ovenware, lab, kitchen plates |

| Crystal Glass | Lead/Barium Silica | Up to 160°C | Medium | 95% | FDA | Tableware, decorative |

9 Inch 10 Inch Stained High Borosilicate Glass Plate: Excellence in Kitchen Glasses

The 9 Inch 10 Inch Stained High Borosilicate Glass Plate is a leading-edge product designed for the most demanding kitchen environments. Borosilicate glass contains about 13-15% boron trioxide (B2O3), granting it extraordinary thermal shock resistance, chemical stability, non-porosity, and clarity.

Key product features:

Key product features:

- Available diameters: 9 and 10 inches (228/254mm).

- Thickness: 7-11mm

- Material: Borosilicate glass (SiO2 75%, B2O3 13%, Al2O3 2%, Na2O 7%)

- Stained finish for anti-fingerprint and custom design

- Temperature tolerance: -40°C ~ +500°C

- Impermeable, food-safe, compliant with ISO 9001:2015, ANSI Z97.1, and FDA Food Contact standards

- Service life: > 7 years (when adherence to EN 1183 is maintained)

Manufacturing Process for Kitchen Glasses (With Diagram)

Raw Material Selection

→

Mixing & Melting (≥1500°C)

→

Molding/Forming

→

Annealing

→

Surface Staining & CNC Cutting

→

Quality Inspection

→

Packaging & Delivery

- Raw Material Selection: Strict adherence to ISO 12775; only high-purity silica sand, boric acid, sodium carbonate, and aluminum oxide are used.

- Mixing & Melting: Raw batch is heated in fusion furnaces (≥1500°C) for homogeneity.

- Molding/Forming: CNC-controlled forming for plate or custom shapes ensures perfect roundness and uniformity.

- Annealing: Precise temp-controlled annealing relieves internal stresses (per ISO 7884-8 protocol).

- Surface Staining & CNC Cutting: Ions are diffused under vacuum conditions for lasting anti-fingerprint and decorative finish.

- Quality Inspection: ASTM C162 and EN 1183 thermal shock, impact, and optical clarity tests.

- Packaging & Delivery: Plates are poly-wrapped, pass drop-test per ANSI Z97.1, and ready for worldwide distribution.

Technology Advantages & Application Scenarios

Thermal and Mechanical Advantages:

- Withstands rapid thermal changes up to 180°C without shattering (ACS Materials, 2023).

- Hardness of 6.8 Mohs, scratch-resistant and abrasion-proof.

- Zero porosity, prevents bacterial growth and chemical leaching.

- Foodservice: Commercial canteens, fast-food chains for hygienic and long-lasting serving plates.

- Catering: Decorative platters for gourmet presentations with anti-stain technology.

- Industrial: Chemical, metallurgy, water treatment as sample trays due to chemical inertness.

- Household: Microwave, freezer, and oven-to-table safe, effortless cleaning and non-reactive functionality.

Case Study: In 2023, a U.S. hospital cafeteria replaced 83% of their plates with borosilicate glass. Result: Annual breakage rates dropped by 77%, chemical detergent usage for cleaning fell 38%, and average service life rose by 68%. User satisfaction (measured via HCAHPS) increased by 1.4 pts post-upgrade.

Product Technical Data: Visual Analysis

Table: Technical Comparison – 9" vs 10" Stained High Borosilicate Glass Plate

| Specification | 9 Inch Plate | 10 Inch Plate | Soda-Lime Reference |

|---|---|---|---|

| Diameter (mm) | 228 | 254 | 230-255 |

| Thickness (mm) | 7–10 | 8–11 | 6–10 |

| Weight (g) | 450±20 | 530±25 | 500±30 |

| Thermal Resistance (°C) | -40~500 | -40~500 | 0~120 |

| Impact Strength (KJ/m2) | 20.8 | 21.2 | 11.0 |

| Transparency (%) | 93 | 93 | 92 |

| FDA/ISO Compliance | Yes | Yes | Rarely |

| Average Lifespan (years) | 7+ | 7+ | 2–3 |

Impact Strength Comparison

Thermal Resistance Distribution

Material Composition (Pie)

Vendor Competitive Landscape: Kitchen Glasses Manufacturers

Top International Vendors (Sample, 2024):

- Yinto Glassware – 9/10-Inch High Borosilicate Plates. 17+ years, ISO 9001 certified, served 600+ commercial clients (Accor, Marriott, Philips).

- Borosil Ltd. (India) – Lab & cook-grade glass. High-borosilicate with custom coloring.

- Arc International (France) – Tableware & kitchen glasses, broad design range.

- Libbey (USA) – Affordable hospitality glass, mainly soda-lime, 4-year avg. lifespan.

Customization Solutions For Kitchen Glasses

Yinto Glassware offers fully customized kitchen glasses solutions:

- Logo & Color Staining: Choose from >23 color shades. Ions-embedding tech for anti-fingerprint, dishwasher-proof decoration.

- Size/Shape Modification: CNC shaping allows rounds, ovals, rectangles, and bespoke patterns; diameter ±1mm tolerance.

- Edge Processing: Polished, beveled, or anti-chip edges per site safety needs (EN 14749 compliant).

- Etching & Printing: Custom logos or measurement marks, up to 0.1mm precision.

- Packaging Options: Poly-wrap, foam-insert boxed sets, and drop-tested bulk solutions.

Typical Application Cases

Hotel Industry (Europe): In 2022, “ArcticHome Hotel Group” deployed 3,000 pieces of custom 10" stained plates from Yinto. Over 12 months, breakage was <2%, a sharp contrast to the prior 7% using toughened soda-lime. Cleaning efficiency improved by 30%, with zero detected leaching/odor.

Food Processing: ISO/FDA-compliant borosilicate trays for automated bakery chains. Plates survived over 850 oven cycles before visual wear (test lab: SGS 2023).

Home Use: Customers rate borosilicate kitchen glasses at 4.85/5.0, citing “no scratches despite heavy utensils,” and “always sparkling clear after dishwasher.”

Industry Certification & Quality Commitment

- ISO 9001:2015 (quality management)

- ANSI Z97.1 (safety glazing in building materials)

- FDA Food Contact (non-leaching, non-reactive surfaces)

- EN 1183 (thermal shock resistance)

- ASTM C162 (glass sheet integrity)

18 years of professional service, ISO/FDA-certified, with over 650,000 pcs delivered and audited by TÜV Rheinland.

Professional FAQ: Kitchen Glasses Industry Terminologies

1. What is borosilicate glass and why is it used for kitchen glasses?

Borosilicate glass contains significant boron trioxide (B₂O₃), granting it high resistance to thermal shock (up to 500°C), chemical corrosion, and mechanical impact. This makes it ideal for commercial and domestic culinary glassware that repeatedly faces rapid temperature and chemical changes.

2. What are the typical thickness and size tolerances?

For 9" and 10" plates, thickness is 7-11mm, with diameter tolerance of ±1mm, exceeding EN ISO 10545-2 kitchenware requirements.

3. What certifications should reliable kitchen glasses hold?

Key international certifications include ISO 9001 (quality), FDA/EN 1183 (safety/food contact), and ANSI Z97.1 (impact & breakage safety).

4. How are anti-fingerprint and colored stains applied?

Through vacuum ion diffusion and CNC-controlled pattern embedding, ensuring uniformity, durability, and dishwasher-resistance.

5. How is thermal shock resistance measured?

Using the EN 1183 standard, the plate is rapidly subjected to temperature changes; passing requires no cracks or permanent deformation between -40°C and 180°C increments.

6. What is the expected service life?

Properly maintained high-borosilicate plates have a ≥7 year lifespan under typical restaurant cycles (~3 washes/day, continuous hot/cold transitions).

7. How is glass edge safety ensured?

CNC polishing and optional beveling per EN 14749; drop and impact tests confirm chip-and-crack resistance before shipment.

Ordering, Warranty & Customer Support

- MOQ: 240 pcs per SKU, supports flexible OEM/ODM.

- Production Lead Time: 14~28 working days (dependant on custom requirements)

- Global Delivery: Air, sea, train options; verified by SGS third-party inspection

- Warranty: 2-year replacement warranty against manufacturing defects

- Support: Free technical consulting, 24h online customer care, in-depth aftersales troubleshooting

- Samples: 3-7 days delivery, with refundable sample cost upon order

All products pass pre-shipment quality control, with analysis reports available on request.

Why Choose High Borosilicate Kitchen Glasses From Yinto?

- Best-in-class material purity and anti-stain surface finishes

- Certified safe for food contact worldwide

- Exceptional lifecycle cost efficiency—less frequent breakage, lower replacement spend, reduced cleaning costs

- Backed by international project cases and favorable client satisfaction data

- Green, recyclable, and compliant with global environmental directives

Conclusion & References

Advanced kitchen glasses—especially high-borosilicate plates—are transforming commercial and home kitchens with their unique combination of safety, endurance, and modern aesthetics. As quoted from Glass Technology European Journal (2023): “Borosilicate culinary glassware sets a new benchmark for thermal, hygienic, and visual standards in foodservice.”

- Glass Technology European Journal: https://www.ingentaconnect.com/content/stl/gt

- Glass Packaging Institute: https://www.glass.org/

- ISO 9001:2015 Official: https://www.iso.org/standard/62085.html

- FDA Food Contact Regulations: https://www.fda.gov/food

Latest news

-

Unparalleled Convenience by High Borosilicate Glass Bottle with a Cork LidNewsJul.17,2025

-

The Versatility and Convenience of Glass Salad Bowl SetsNewsJul.17,2025

-

The Practical Wide Application of High Borosilicate Glass Food Storage ContainerNewsJul.17,2025

-

High Borosilicate Colored Glass Bowl VS Soda-Lime Glass and Tempered GlassNewsJul.17,2025

-

Creativity with Customized Colored Glass Dinnerware Sets for SaleNewsJul.17,2025

-

Advantages Analysis of Double Wall French PressNewsJul.17,2025

Related Products