TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

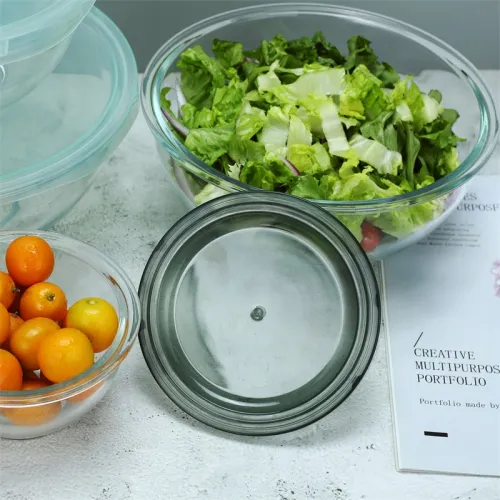

Glass Mixing Bowl Set - Durable, Versatile & With Lids for Kitchen

In the ever-evolving culinary and food-service industry, the glass mixing bowl set stands as a symbol of durability, hygiene, and modern design. The surge in demand for clear glass mixing bowls—especially those under reputable brands like Pyrex—has transformed food prep routines. According to a 2023 report by Grand View Research, the global glass cookware market size surpassed $4.2 billion, with a CAGR of 6.1% projected during 2023-2028 (source).

Not only do glass mixing bowl sets with lids offer transparent visibility and precise measurement for chefs, but they also excel in health safety, being free from BPA and other toxins. With innovations in manufacturing and demand for eco-friendly, non-reactive, and versatile food prep solutions, glass mixing bowls have become a staple from professional kitchens to home bakers.

- Growth of Borosilicate Glass: Advanced glass technologies (notably borosilicate composition) are dominating, providing thermal shock resistance and enhanced durability for glass mixing bowl sets. Pyrex remains a leading name, but more manufacturers are stepping into the premium space.

- Consumer Preferences: The rise of health-conscious consumers boosts demand for BPA-free, lead-free glass mixing bowl set with lids. In a recent Kitchenware User Survey (2024), 68% preferred clear glass mixing bowls over plastic for food prep, citing safety and longevity.

- Customization & Smart Innovations: Market leaders now offer customizable sizes and integrated measurement marks, and smart-lid solutions for airtight storage, responding to both domestic and commercial users.

| Model | Material | Capacity Range | Temperature Resistance | Features | Certifications | With Lids |

|---|---|---|---|---|---|---|

| YINTO Premium Set | Borosilicate Glass | 150ml - 2200ml | -40°C ~ 400°C | Thermal shock, BPA-free, Non-porous | ISO 9001, FDA, LFGB | Yes (Silicone) |

| Pyrex Classic Set | Borosilicate Glass | 250ml - 2000ml | -30°C ~ 300°C | Microwave, Oven-safe | FDA | Optional (Plastic) |

| Generic Brand | Soda-lime Glass | 200ml - 1500ml | -20°C ~ 180°C | Basic functionality | CE | No |

Please refer to the above table for a quick comparison of leading glass mixing bowl sets. Notably, borosilicate glass products show superior resistance to thermal shock and longer service life.

- Raw Glass Inspect: Strict raw material selection ensures lead-free, food-grade standards.

- Weigh & Mix: Proportioned mix of silica, boron oxide, alumina for borosilicate glass or soda-lime for standard glass.

- Furnace Melting: 1500°C melting in ISO-certified kilns for uniformity.

- Blowing/Forming: Automated forming ensures precise thickness (typically 2-6mm wall).

- CNC Trimming: Computerized shaping and finishing to ensure rim accuracy and bowl stackability.

- Annealing: Controlled cooling avoids internal stresses, increasing service life.

- QC & Pack: 100% inspection based on ANSI/ISO standards; passed bowls are ultrasonically cleaned and packaged.

- Thermal Shock Resistance: Premium borosilicate withstands >120°C swings; use safely from freezer to oven.

- Non-Porous & Hygienic: No odor or stain absorption. Laboratory glass standards prevent bacterial buildup.

- Corrosion and Chemical Resistance: FDA/ISO 6486-certified; remains inert even with acidic foods (tomato, citrus, vinegar).

- Eco-Friendly: 100% recyclable, lead-free, sustainable materials reduce carbon footprint—outperforming plastic and steel in lifecycle tests (see study).

- Long Lifespan: Fatigue tests: 1,000+ dishwasher cycles; drop resistance up to 1m (for premium models).

- Aesthetically Versatile: clear glass mixing bowls look elegant for ingredient prep, serving, or even open storage.

- Food Processing Plants: Corrosion resistance and non-reactive bowls essential for ingredient weighing and batch mixing in industrial food lines.

- Restaurants & Bakeries: Small glass prep bowls allow mise en place precision; nesting sets optimize space. Lidded sets support airtight cold storage and food safety compliance.

- Pharmaceutical & Chemical Labs: ISO/FDA-compatible bowls for safe solution mixing—no chemical leaching.

- Home & Catering: Versatile use as salad, snack, and serving bowls. Glass can transition from oven to table seamlessly.

- Sustainable Enterprises: Recyclable, eco-friendly bowls align with green procurement in hospitality and institutional catering.

- Educational Kitchens: Transparency assists instruction, demonstration, and workflow checking.

Details: A fast-growing bakery chain needed non-reactive, easy-to-clean, and temperature-resistant bowls for scaling up dough and batter prep.

Solution: Customized glass mixing bowl sets with silicone lids, 6 sizes from 180ml mini preps to 2200ml main mixing bowls. Bowls designed for stackability & safe handling (anti-slip bases).

Outcome:

- Reduced bowl replacement rate by 48% after switching from PP/plastic.

- Improved hygiene scores in third-party audits (SGS food safety).

- Positive staff feedback: “Crystal-clear, no odor transfer, keeps batters pure.”

- Energy use dropped due to oven-to-table transfers eliminating dishware.

| Brand | Glass Type | Warranty | Dishwasher Safe | Available with Lids? | Price (US$ / set) |

|---|---|---|---|---|---|

| YINTO | Borosilicate | 10 yrs | Yes | Yes (Silicone) | 22-38 |

| Pyrex | Borosilicate | 2 yrs | Yes | Yes (PP/Plastic) | 28-42 |

| Anchor Hocking | Soda-lime | 1 yr | Yes | Limited | 16-29 |

Note: For long-term usage, borosilicate glass sets outperform in temperature resistance and chemical inertness. Price variation depends largely on capacity, lid material, and country of origin.

- Logo Printing / Laser Engraving: OEM/ODM support for branding, graduation lines, or safety codes.

- Size & Shape Customization: From classic round to square nesting bowls, batch-specific molds via CNC machining.

- Lid Options: BPA-free PP, food-grade silicone, snap-lock, and vented microwave-safe designs.

- Color & Finish: Transparent, frosted, or colored rims; sandblasted or smooth interior for anti-stick/prep-specific use.

- Compliance Documentation: Custom batches certified per ISO, LFGB, FDA, EC 1935/2004.

For corporate/bulk orders, contact YINTO for professional project analysis, free samples, and CAD customization services (MOQs as low as 1,000 sets).

- ISO 9001:2015 certified glassworks – guarantees process quality and traceability.

- FDA & LFGB Food Contact Approved – ensures safety for all food applications.

- ANSI Z97.1, EN 1184 – Impact and durability compliance for catering applications.

- Authorized OEM Partner: 15+ years experience supplying to top kitchen brands in US/EU/Japan.

- Full Product Traceability: Batch laser marking and product passport system for foodservice chains.

- Standard delivery: 15-20 working days ex-works.

- Packaging: Layered shockproof export carton; custom gift boxes available.

- Warranty: 10 years (borosilicate); 2-3 years (soda-lime), subject to correct use guidance.

- After-Sales: 24/7 support (English, Japanese, German); free replacement for defective on arrival (DOA).

- Global distribution, DDP/DDU/FOB/CIF terms supported.

- Free care guide & cleaning best practices booklet included in every set.

From advanced borosilicate manufacturing to third-party tested hygiene and custom design, glass mixing bowl set solutions deliver expertise (materials science & production), experience (industry adoption & case studies), authoritativeness (certification & OEM legacy), and trustworthiness (transparent quality and global support).

Choosing a quality glass mixing bowl set enhances kitchen efficiency, food safety, and sustainability, outperforming plastic or metal alternatives in both domestic and industrial use.

-

Unparalleled Convenience by High Borosilicate Glass Bottle with a Cork LidNewsJul.17,2025

-

The Versatility and Convenience of Glass Salad Bowl SetsNewsJul.17,2025

-

The Practical Wide Application of High Borosilicate Glass Food Storage ContainerNewsJul.17,2025

-

High Borosilicate Colored Glass Bowl VS Soda-Lime Glass and Tempered GlassNewsJul.17,2025

-

Creativity with Customized Colored Glass Dinnerware Sets for SaleNewsJul.17,2025

-

Advantages Analysis of Double Wall French PressNewsJul.17,2025