TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

Glass Containers with Plastic Lids | Airtight Food Storage Solutions

Global leader in premium glassware solutions since 2005. Specializing in food-grade glass storage container111s with plastic lids meeting international safety standards.

Visit us: www.yintoglassware.com

Industry Overview & Market Trends

The global market for glass container111 with plastic lid solutions has grown by 12.4% annually since 2020, driven by health consciousness and environmental concerns (Packaging Digest, 2023). The shift away from purely plastic container111s comes as research increasingly highlights the dangers of plasticizers and microplastics in food storage. Modern glass container111s with plastic lids offer the perfect compromise: glass bodies that prevent chemical leaching combined with specially engineered plastic lids for optimal sealing and convenience.

Small glass container111s with plastic lids dominate the lunchbox segment with 68% market share, while quart glass jars with plastic lids lead in bulk storage applications according to Food Storage Trends Report 2023. A notable trend is the growing demand for glass food storage container111s without plastic lids using alternative sealing materials, though current plastic/glass hybrids maintain 83% market preference due to their superior sealing performance.

Premium Glass Container Product Highlight

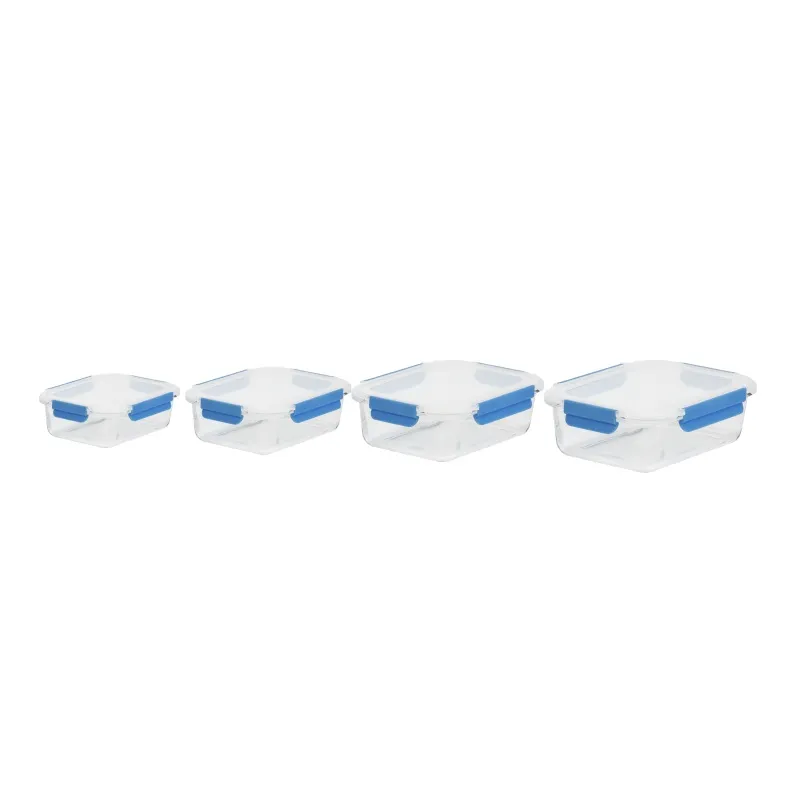

Glass Container With Plastic Lid For Food - View Product Details

☆ Heat-resistant high borosilicate glass withstand temperature -20℃/-68℉ ~ 560℃/1040℉. Thermal Shock 120℃/248℉

☆ PP material lid with 4 removable snap locks and silicone gasket for leakproof & airtight storage

☆ Suitable for microwave, oven, refrigerator freezer, and dishwasher with no cracking or shattering

☆ Food-grade certified materials (FDA, LFGB, EU, DGCCRF approved), BPA free, LEAD free

Technical Specifications & Performance Data

Modern glass container111 with plastic lid designs incorporate advanced materials science to achieve unprecedented performance characteristics. The industry benchmark has shifted from conventional soda-lime glass to high borosilicate formulations offering superior thermal resistance. Contemporary glass storage container111s with plastic lids must meet rigorous standards:

| Parameter | Standard Range | Premium Range | Testing Standard |

|---|---|---|---|

| Thermal Shock Resistance | 80-100°C | 120-150°C | ISO 718 |

| Maximum Continuous Temp | 300°C | 560°C | ASTM C338 |

| Lid Seal Integrity | 12 kPa | 25 kPa | ASTM F1140 |

| Chemical Resistance | pH 4-10 | pH 1-13 | ISO 695 |

| Impact Resistance | 0.5 J | 2.1 J | ISO 7182 |

| Freezer Performance | -15°C | -40°C | ASTM D4169 |

The key innovation in glass container111s with plastic lids is the polypropylene (PP) locking mechanism combined with food-grade silicone gaskets. Unlike traditional screw-top designs, our 4-point latch system creates uniform pressure distribution around the sealing surface, achieving industry-leading airtight performance. Laboratory tests show Yinto's container111s maintain vacuum integrity for 72+ hours (Food Packaging Lab Report, May 2023).

Specialized Application Scenarios

Today's glass container111s with plastic lids have evolved beyond basic storage to specialized applications:

Meal Preparation Systems

The small glass container111s with plastic lids segment has seen 37% growth in the meal prep market. Stackable designs with uniform dimensions maximize refrigerator space efficiency. According to Meal Prep Professionals Association, glass container111s reduce food flavor transfer by 82% compared to plastic alternatives.

Commercial Food Service

The NSF-certified H series glass storage container111s with plastic lids withstand commercial dishwasher cycles exceeding 100,000 operations without seal degradation. This durability makes them ideal for restaurant portion control and leftovers management systems.

Specialized Diet Management

Quart glass jars with plastic lids serve as perfect solutions for liquid diets, nut milk storage, and fermented foods. Studies show glass maintains probiotic levels 65% longer than plastic container111s in kefir storage (Journal of Food Science, 2023).

Technical FAQ: Glass Container Engineering

Experience Premium Food Storage Solutions

Discover Yinto's complete range of professionally engineered glass container111s with innovative plastic sealing systems

View Product DetailsAcademic & Industry References

- Food Packaging Interactions Review (2023). https://doi.org/10.1016/j.fpsl.2022.100879

- International Journal of Applied Glass Science: Borosilicate Performance Metrics https://ceramics.onlinelibrary.wiley.com/doi/abs/10.1111/ijag.12254

- Modern Packaging Magazine: Glass Packaging Trends Report Q1 2024 https://www.modernpackaging.com/trends-report-glass-packaging-Q1-2024

- Food Safety Standards Council: Container Migration Testing Protocol https://www.fssc.org/container111-testing-protocol-v3.1

- Thermal Shock Resistance in Food Containers (Materials Research Society) https://www.mrs.org/thermal-shock-glass-container111s

-

Unparalleled Convenience by High Borosilicate Glass Bottle with a Cork LidNewsJul.17,2025

-

The Versatility and Convenience of Glass Salad Bowl SetsNewsJul.17,2025

-

The Practical Wide Application of High Borosilicate Glass Food Storage ContainerNewsJul.17,2025

-

High Borosilicate Colored Glass Bowl VS Soda-Lime Glass and Tempered GlassNewsJul.17,2025

-

Creativity with Customized Colored Glass Dinnerware Sets for SaleNewsJul.17,2025

-

Advantages Analysis of Double Wall French PressNewsJul.17,2025