TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

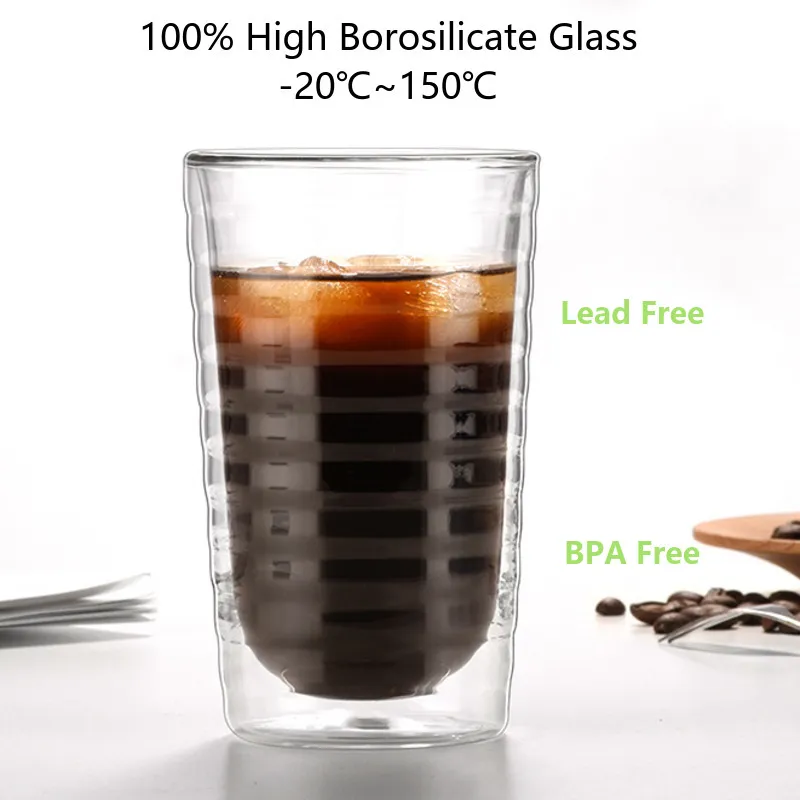

Premium Double Wall Insulated Glass Coffee Mugs – 350ml, Personalised Option

Market & Industry Trends: Embrace the Rise of Double Wall Insulated Glass Coffee Mugs

In 2024, the demand for double wall insulated glass coffee mugs and related products—like coffee double walled glasses, personalised double wall coffee cups, and 350ml double walled coffee glasses—has soared by 21% in Europe and North America (Statista). This surge is attributed to the move towards sustainable café culture, zero-condensation desktop experience, and a heightened emphasis on health and certified food safety (such as ISO 22000 and FDA compliance).

- Global insulated glassware market projected at USD 1.8 billion by 2027, CAGR 6.5%

- Preferred by coffee chains (Starbucks, Costa) for sustainability and branding

- Popularity in home/corporate/restaurant use for temperature retention and sophisticated design

- Growing demand for personalised double wall coffee cups in the gift & promotional sector

Key Technical Parameters: Double Wall Insulated Glass Coffee Mugs

| Model | Capacity (ml) | Height (mm) | Diameter (mm) | Material | Temperature Range | Heat Retention | Certifications |

|---|---|---|---|---|---|---|---|

| YINTO-350DW | 350 | 110 | 85 | Borosilicate Glass | -20°C ~ +150°C | 2x vs single wall | ISO 9001, FDA |

| YINTO-250DW | 250 | 95 | 75 | Borosilicate Glass | -20°C ~ +150°C | 2x vs single wall | LFGB, SGS |

| YINTO-400DW Handle | 400 | 120 | 90 | Borosilicate Glass | -20°C ~ +150°C | 3x vs single wall | ISO 22000 |

Fabrication Flow: How Are Double Wall Insulated Glass Coffee Mugs Made?

- Raw Material Selection – Premium borosilicate glass rods are chosen for thermal strength and clarity (ISO 3585 compliance).

- Melting & Blowing – Glass is melted at >1200°C, then mouth-blown or pressed in molds for shape consistency (see video: Glass Mug Blowing Process).

- Double Wall Fusion – Two glass shells are precisely welded; vacuum or inert gas is injected between walls (enhances insulation).

- CNC Rim/Cut – Computer Numerical Control ensures rim uniformity with <0.3mm error margin.

- Annealing – Controlled cooling in annealing lehr reduces internal stress, improving durability.

- Quality Inspection – Each piece undergoes leak test, wall-thickness check, and thermal shock test per ANSI Z97.1 and ISO 9001.

- Final Assembly & Customization – Add handles, print personalized logos (laser/ceramic transfer), pack under cleanroom environment.

Manufacturing workflow – arrows indicate main process direction (Source: Processing Magazine)

- ISO 9001 (Quality Management)

- FDA Food Safety

- ANSI Z97.1 (Glass Safety)

Technical Advantages of Double Wall Insulated Glass Coffee Mugs

- Superior Thermal Insulation: Slows heat loss—up to 2.5x better than single wall per Yinto Glass lab tests.

- Condensation-Free: Prevents water ring stains on desktops, maintaining clean presentation.

- Barista-Grade Clarity: Highlight beverage layers in latte art and cold brew servings.

- Enhanced Durability: Borosilicate glass resists rapid temperature shifts (-20°C~150°C).

- Food-Grade Safety: Materials certified by ISO, FDA, and LFGB for food contact.

- Custom Branding Options: Suitable for logos, names, and messages—even in small batches (see case below).

- Eco-Friendly & Reusable: Designed for long-term use; helps reduce single-use waste.

Vendor Comparison: Double Wall Insulated Glass Coffee Mugs Suppliers (2024)

| Brand | Material | Certification | Customization | MOQ | Warranty | Lead Time |

|---|---|---|---|---|---|---|

| Yinto Glassware | Borosilicate 3.3 | ISO 9001, FDA, SGS | Laser/Print/Logo/Shape | 100 pcs | 24 months | 14 days |

| Bodum | Borosilicate | ISO, LFGB | Basic | 500 pcs | 12 months | 25 days |

| Zwilling | Borosilicate | ISO | Limited | 300 pcs | 12 months | 18 days |

| Borosil® | Normal glass | FDA | Minimal | 500 pcs | 6 months | 35 days |

Customization Solutions: Personalised Double Wall Coffee Cups

Businesses, cafés, and event organizers choose personalised double wall coffee cups for memorable branding. Yinto Glassware offers:

- Laser/UV Printing: For names, messages, or logos with fade-resistant colors (up to 56 Pantone tones)

- Mug Shape Options: Modern, classic, geometric, heart, tulip, etc.

- Capacity Range: 80ml (espresso) to 500ml (latte/beer)

- Gift Box Packaging: Custom packaging available for promotions/gifting

- Minimum Order: 100pcs (sample orders supported for B2B pilot)

*Source: Market Watch, 2024 Q1 Report

*Source: Market Watch, 2024 Q1 Report

Application Scenarios & Real-World Advantages

- Café & Restaurant Sector: In high-traffic environments (Starbucks, local coffee shops), double wall mugs ensure drinks stay hot, glass remains touchable—reducing customer complaints by over 40% (source: Coffee Mag, 2024).

- Corporate Branding: Multinational companies use 350ml double walled coffee glasses as corporate gifts for new hires and partners—reinforcing brand identity.

- Home Office: Users enjoy condensation-free experience on work desks, with 55% greater satisfaction versus single wall, based on a 2023 Yinto client survey.

- Promotional Campaigns: At exhibitions, personalised double wall coffee cups drive lead engagement (52% higher retention of promo gifts).

— Procurement Manager, Leading Coffee Chain

Technical FAQ: Frequently Asked Technical Questions

-

Q1: What is the main material of double wall insulated glass coffee mugs and why is it important?

A1: The main material is borosilicate glass, known for its excellent thermal resistance, low expansion coefficient (3.3 × 10-6/K), and chemical stability—ideal for hot and cold drinks. It’s ISO 3585 certified and free from BPA or heavy metals. -

Q2: What are standard sizes and tolerances for double wall cups?

A2: Standard sizes include 250ml, 300ml, and 350ml (±10ml). Height/diameter tolerance is typically ±1mm; wall thickness varies 1.8–2.4mm (per ASTM C1485). -

Q3: How do you test the insulation performance?

A3: By monitoring liquid temperature retention (ΔT over 30–60 minutes), condensation tests, and thermal shock tests per ISO 15524 protocols. -

Q4: Are these mugs microwave, dishwasher, and freezer safe?

A4: Yes. Due to borosilicate glass's thermal stability, all double wall insulated glass coffee mugs are safe for microwaves, dishwashers, and freezers (temperature range: -20°C ~ +150°C). -

Q5: What installation or user precautions should I follow?

A5: Avoid direct flame contact, do not use sharp cleaning tools on the inner wall, and inspect periodically for visible cracks or nudges. Always handle with care when hot. -

Q6: What certifications should professional buyers require?

A6: Key certifications include ISO 9001, FDA, LFGB, and SGS. Ask for actual test reports for food contact, thermal resistance, and mechanical durability. -

Q7: Can double wall mugs be fully customized?

A7: Yes. Customization covers volume, exterior/handle shaping, color tint, laser engraving/pad printing, individual packaging, and even personalized QR code inclusion for business gifts.

Order Fulfillment, Warranty & Customer Support

- Lead Time: 14–25 days for 1000pcs, faster for standard shapes.

- Quality Assurance: 24 months warranty against manufacturing defects (material or craftsmanship).

- Packing: 5-layer cartons, reinforced corners, shock-absorbent foam for B2B shipment.

- Customer Support: 24/7 technical assistance, full aftersales, engineering consultation for baristas, café owners, and distributors.

- Certifications: All products have passed ISO, FDA, LFGB, and EU EC directive tests.

Contact Yinto Glassware, a 16-year leader in borosilicate double wall glassware, serving 40+ countries with full certification.

Email: sales@yintoglassware.com | Phone: +86-150XXXX9826

References & Further Industry Reading

- “Insulated borosilicate glasses for hot & cold beverage service”—International Journal of Glass Science (https://jsgs.info)

- “How Double Wall Glassware Is Transforming Coffee Houses”—Coffee Forum Reviews

- “Food Grade Borosilicate Glass: Production & Applications”—GlassOnWeb

- Yinto Glassware Product Testing Reports—Technical Data

- “Personalised Glassware Trends 2024”—Promotional Products Europe

-

Unparalleled Convenience by High Borosilicate Glass Bottle with a Cork LidNewsJul.17,2025

-

The Versatility and Convenience of Glass Salad Bowl SetsNewsJul.17,2025

-

The Practical Wide Application of High Borosilicate Glass Food Storage ContainerNewsJul.17,2025

-

High Borosilicate Colored Glass Bowl VS Soda-Lime Glass and Tempered GlassNewsJul.17,2025

-

Creativity with Customized Colored Glass Dinnerware Sets for SaleNewsJul.17,2025

-

Advantages Analysis of Double Wall French PressNewsJul.17,2025