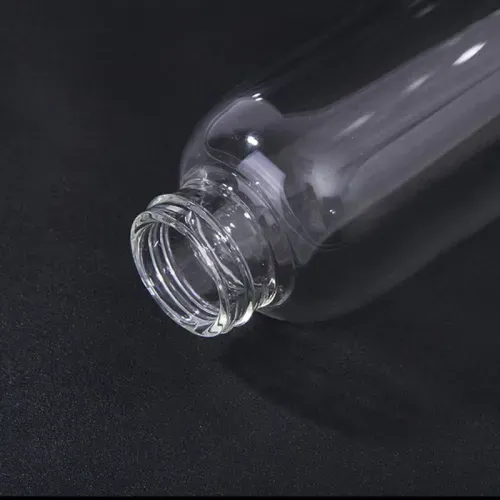

An extra large glass measuring cup is typically made from durable, heat-resistant borosilicate glass, which allows for accurate measurements and can withstand high temperatures. These cups often come in sizes of 4 quarts or more, making them perfect for both large batches of recipes and for mixing ingredients together. One of the most significant benefits of a glass measuring cup is its clarity. The transparent nature of glass allows cooks to see the contents clearly, making it easier to gauge the quantity of ingredients being used.

Home

Home