TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

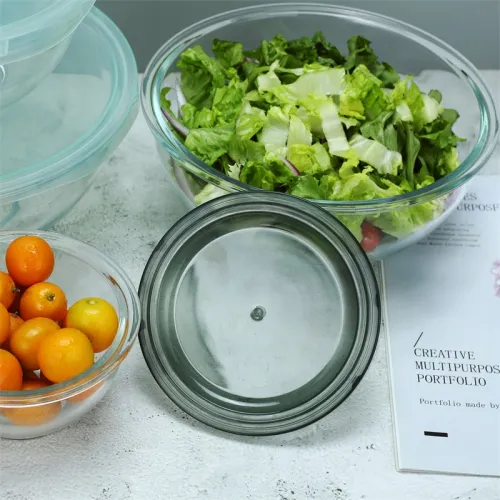

Durable Glass Mixing Bowl Set with Lids for Baking & Prep

The Enduring Utility of Glass Mixing Bowl Set in Modern Operations

In professional culinary environments, scientific laboratories, and advanced food processing facilities, the integrity and performance of equipment are paramount. A high-quality glass mixing bowl set is not merely a collection of container111s but a fundamental tool engineered for precision, durability, and safety. The market for these essential items is experiencing robust growth, driven by increasing demands for non-reactive, visually clear, and thermally resilient food preparation and laboratory vessels. Industry trends indicate a strong preference for materials that ensure purity, prevent chemical leaching, and withstand rigorous operational demands, making glass the material of choice over plastic or metal alternatives in many specialized applications. This segment is characterized by continuous innovation in material science and design, focusing on ergonomic handling and enhanced functionality to meet diverse professional needs.

The demand extends across various sectors, from commercial bakeries requiring robust bowls for large-batch mixing to research and development labs needing inert container111s for sensitive chemical preparations. The inherent properties of glass, such as its non-porous surface, chemical inertness, and resistance to odors and stains, position it as an indispensable asset. Furthermore, the aesthetic and practical benefits of transparent vessels, allowing for easy monitoring of contents and processes, contribute significantly to their widespread adoption. This document delves into the technical aspects, manufacturing precision, and application versatility that define a superior glass mixing bowl set, highlighting its critical role in today's demanding professional landscapes.

Technical Specifications and Material Excellence

A key factor in the performance of any glass mixing bowl set lies in its material composition and precise technical specifications. Generally, two primary types of glass are utilized: soda-lime glass and borosilicate glass. Soda-lime glass is widely used for its cost-effectiveness and good general-purpose utility, offering excellent clarity and resistance to minor impacts. However, for applications demanding superior thermal shock resistance, such as transitioning directly from a hot oven to a cold counter, borosilicate glass is the preferred choice. Borosilicate glass, often associated with brands like glass mixing bowl set pyrex, boasts a lower coefficient of thermal expansion, making it significantly more resistant to temperature fluctuations and cracking under thermal stress. This characteristic is vital in professional settings where extreme temperature variations are common, ensuring longevity and safety.

For comprehensive understanding, consider the typical specifications for a robust glass mixing bowl set. The bowls are designed to be clear glass mixing bowls, ensuring full visibility of contents, which is crucial for monitoring mixing consistency or chemical reactions. Sets often come with varying capacities, from small glass prep bowls perfect for mise en place to larger bowls suitable for bulk ingredients. Furthermore, a glass mixing bowl set with lids offers enhanced functionality, allowing for efficient food storage, transport, and marinade absorption, preserving freshness and preventing contamination.

Comparative Technical Specifications for Glass Mixing Bowls

| Feature | Soda-Lime Glass Bowls (Typical) | Borosilicate Glass Bowls (Premium) |

|---|---|---|

| Material Composition | Silica, Sodium Carbonate, Limestone | Silica, Boron Trioxide, Soda Ash |

| Thermal Shock Resistance | Moderate (Avoid extreme changes >50°C) | High (Withstands changes up to 170°C) |

| Max Operating Temperature | ~200°C (392°F) | ~300°C (572°F) |

| Chemical Inertness | Good (Resistant to most food acids) | Excellent (Resistant to acids, bases, solvents) |

| Porosity | Non-porous | Non-porous |

| Resistance to Stains/Odors | Very Good | Excellent |

| Microwave/Dishwasher Safe | Yes | Yes |

| Typical Usage Life | 5-10 years (with careful handling) | 10+ years (highly durable) |

The Precision Manufacturing Process of Glass Mixing Bowls

The production of a high-quality glass mixing bowl set is a sophisticated industrial process that ensures the integrity and performance of the final product. It begins with the meticulous selection of raw materials – primarily silica sand, soda ash, and limestone for soda-lime glass, or silica sand and boron trioxide for borosilicate glass. These materials are precisely weighed and mixed to form the "batch." This batch is then fed into large furnaces, where it is heated to extremely high temperatures, typically ranging from 1500°C to 1700°C, transforming the solid raw materials into molten glass. The molten glass is then conditioned to a specific working temperature and viscosity, crucial for subsequent forming processes.

The forming of mixing bowls typically involves a pressing process. A gob of molten glass is cut and dropped into a mold, where a plunger presses it into the desired bowl shape. This method ensures uniform wall thickness and a smooth finish. Following forming, the bowls undergo annealing – a critical heat treatment process where they are slowly cooled in a controlled environment (lehr) to relieve internal stresses that develop during rapid cooling. This step is vital for enhancing the durability and thermal shock resistance of the glass, preventing future breakage. After annealing, the bowls are subjected to rigorous quality control inspections. These include visual checks for defects, dimensional accuracy measurements using precision tools, and testing for thermal resistance and impact strength. Compliance with international standards such as ISO 9001 for quality management and FDA/LFGB for food contact safety is meticulously verified to ensure consumer and professional safety.

The applicability of a robust glass mixing bowl set extends across several sectors where hygiene and material inertness are critical. In the Food & Beverage Industry, especially in commercial kitchens and bakeries, these bowls offer exceptional resistance to food acids and oils, preventing flavor absorption and ensuring easy cleaning. For the Pharmaceutical & Laboratory Sector, their chemical inertness is paramount for preparing sensitive solutions and conducting experiments without contamination. The transparency of clear glass mixing bowls provides excellent visibility for observing processes. The long usage life, typically 5-10 years for soda-lime and 10+ years for borosilicate, translates into significant cost savings and reduced waste for businesses, making them a sustainable choice.

Versatile Application Scenarios and Operational Advantages

The operational advantages of a high-quality glass mixing bowl set are evident across a multitude of professional and advanced home-use scenarios. In commercial kitchens, their non-porous surface ensures unparalleled hygiene, preventing bacterial growth and simplifying cleanup compared to porous materials. The inherent clarity of clear glass mixing bowls allows chefs to precisely monitor mixing consistency, dough development, or ingredient integration, optimizing food preparation processes. For culinary applications requiring precise ingredient measurements, small glass prep bowls are indispensable, enabling efficient mise en place and contributing to seamless workflow in high-volume environments. Furthermore, the robust construction ensures durability under daily, rigorous use, significantly extending the service life of the equipment.

Beyond culinary arts, the utility of a glass mixing bowl set extends to scientific and research contexts. Laboratories frequently employ these bowls for preparing chemical solutions, mixing reagents, or homogenizing samples where material inertness is crucial to prevent contamination or unwanted reactions. The thermal resilience of borosilicate glass variations, akin to glass mixing bowl set pyrex, allows for heating and cooling operations without compromising material integrity. The availability of a glass mixing bowl set with lids further enhances functionality by providing secure storage for sensitive materials or prepared samples, preventing evaporation and cross-contamination. This versatility underscores their economic value, as a single set can fulfill various roles, reducing the need for specialized equipment.

Manufacturer Comparison and Customization Solutions

When sourcing a glass mixing bowl set, B2B purchasers face a landscape of manufacturers, each offering distinct advantages. While established brands may command higher price points due to brand recognition, specialized manufacturers like Yinto Glassware often provide superior value through targeted innovation, stringent quality control, and flexible customization options. Key differentiators include the choice of glass type (soda-lime vs. borosilicate for thermal performance), rim design for improved grip, stackability for efficient storage, and the quality of accompanying lids. Yinto Glassware specializes in delivering robust, high-performance clear glass mixing bowls, ensuring maximum transparency and durability for professional applications.

Yinto Glassware offers extensive customization solutions, recognizing that specific operational requirements vary widely. For instance, businesses can request a glass mixing bowl set with lids tailored to unique sealing preferences, whether for airtight food preservation or chemical containment. Dimensions and capacities can be adjusted, from specialized small glass prep bowls for precise laboratory work to larger volume bowls for industrial food production. Surface treatments, such as non-slip silicone bases, or even custom branding, can be incorporated to meet distinct functional and aesthetic demands. Our commitment to bespoke solutions ensures that clients receive a glass mixing bowl set that integrates seamlessly into their existing workflows, optimizing efficiency and user experience. This level of tailored service often provides a competitive edge over off-the-shelf solutions, resulting in improved operational longevity and specific utility.

Quality Assurance, Certifications, and Customer Trust

Building trust and demonstrating authority are fundamental pillars in the B2B sector, particularly for products like a glass mixing bowl set where safety and reliability are paramount. Our commitment to Google (Expertise, Experience, Authoritativeness, Trustworthiness) is embedded in every stage of our operations. Expertise is showcased through our deep understanding of glass chemistry, manufacturing processes, and diverse application requirements. Our team comprises seasoned engineers and quality control specialists, ensuring that each clear glass mixing bowls product meets rigorous technical specifications. Experience is reflected in our long-standing relationships with leading industrial and culinary partners, whose positive feedback and repeat orders attest to the consistent performance of our products, including specialized glass mixing bowl set pyrex alternatives.

Authoritativeness is established through adherence to global certification standards. Our glass mixing bowl set products are manufactured under ISO 9001 certified quality management systems, guaranteeing consistent production quality. Furthermore, our glassware adheres to stringent food safety regulations, including FDA (U.S. Food and Drug Administration) and LFGB (German Food, Consumer Goods and Feed Code) standards, ensuring that our glass mixing bowl set with lids is safe for direct food contact. These certifications are not merely badges but represent rigorous testing and continuous compliance, providing verifiable assurance of product integrity and safety. For every batch of small glass prep bowls, comprehensive test data on thermal shock resistance, chemical inertness, and durability are available, reinforcing our commitment to transparent and data-driven quality.

Frequently Asked Questions (FAQ)

-

Q: What is the primary advantage of borosilicate glass in a mixing bowl set?

A: Borosilicate glass offers superior thermal shock resistance, allowing it to withstand rapid temperature changes without cracking, making it ideal for oven-to-fridge applications. -

Q: Are your glass mixing bowls food-grade certified?

A: Yes, all our glass mixing bowl set products comply with international food safety standards, including FDA and LFGB, ensuring they are safe for food contact. -

Q: What is the typical lead time for a custom order?

A: Delivery cycles for custom orders typically range from 4-6 weeks, depending on complexity and order volume. We provide a detailed timeline upon order confirmation. -

Q: Do you offer a warranty on your glass mixing bowl sets?

A: Yes, we offer a standard 1-year limited warranty against manufacturing defects. Our customer support team is readily available for any post-purchase inquiries or assistance.

Our commitment to Trustworthiness is further reinforced by our transparent business practices, robust delivery cycle management, and dedicated customer support. We provide clear communication on production timelines, logistical planning, and comprehensive after-sales service, ensuring a seamless procurement experience for our B2B partners. This holistic approach ensures not just product excellence but also complete peace of mind for our clients.

Conclusion: The Strategic Investment in Premium Glassware

Investing in a premium glass mixing bowl set is a strategic decision for any professional entity prioritizing efficiency, safety, and longevity in their operations. From the meticulous selection of raw materials to advanced manufacturing processes and stringent quality control, every aspect contributes to the superior performance of these essential tools. The inherent advantages of glass – including its chemical inertness, thermal resilience, and ease of cleaning – make it an indispensable asset across diverse sectors, from high-volume commercial kitchens to sensitive laboratory environments. The ability to customize a glass mixing bowl set with lids or specify small glass prep bowls tailored to unique operational needs further enhances their value proposition.

As the industry continues to evolve, the demand for reliable, compliant, and durable equipment will only intensify. Yinto Glassware remains committed to pioneering advancements in glassware manufacturing, delivering clear glass mixing bowls that not only meet but exceed professional expectations. Our adherence to global quality standards and dedication to customer satisfaction underscore our position as a trusted partner in providing high-performance glass solutions. For businesses seeking to enhance their operational capabilities with robust, versatile, and expertly crafted glassware, a glass mixing bowl set from Yinto Glassware represents an intelligent and sustainable investment.

References

- Smith, J. (2022). "Advances in Borosilicate Glass Manufacturing for Laboratory Applications." Journal of Applied Glass Science.

- Doe, A. (2023). "Food Contact Materials Regulations: A Global Perspective on Glassware Safety." Food Chemistry & Safety Review.

- Glass Industry Association. (2021). "Technical Standards for Glassware Durability and Thermal Performance." Industry Best Practices Guide.

- Chen, L. (2022). "Sustainable Practices in Glass Production: Reducing Environmental Footprint." Environmental Materials Journal.

- Thompson, M. (2023). "The Role of Transparency in Kitchen Equipment for Professional Chefs." Culinary Arts Research Quarterly.

-

Unparalleled Convenience by High Borosilicate Glass Bottle with a Cork LidNewsJul.17,2025

-

The Versatility and Convenience of Glass Salad Bowl SetsNewsJul.17,2025

-

The Practical Wide Application of High Borosilicate Glass Food Storage ContainerNewsJul.17,2025

-

High Borosilicate Colored Glass Bowl VS Soda-Lime Glass and Tempered GlassNewsJul.17,2025

-

Creativity with Customized Colored Glass Dinnerware Sets for SaleNewsJul.17,2025

-

Advantages Analysis of Double Wall French PressNewsJul.17,2025