TEL: +86 311 67799298

TEL: +86 311 67799298 Email: tina@yintoglassware.com

Email: tina@yintoglassware.com

Double Glazed Coffee Cups: Keep Drinks Hot, Stay Cool Touch.

Industry Trends & The Rise of Advanced Drinkware Solutions

The global market for advanced drinkware is experiencing a profound transformation, driven by a confluence of evolving consumer preferences, stringent material safety regulations, and a growing emphasis on sustainability. In the B2B sector, particularly within hospitality, corporate gifting, and specialized retail, there is an escalating demand for products that offer more than mere functionality. Clients are seeking solutions that blend sophisticated design with superior technical performance, durability, and health compliance. This market dynamic has significantly propelled the adoption of insulated glassware, with double glazed coffee cups emerging as a leading choice.

Contemporary industry trends indicate a clear shift towards high-quality, reusable drinkware that provides exceptional thermal insulation for both hot and cold beverages. This not only enhances the end-user's experience but also contributes to operational efficiencies for businesses by reducing the need for constant reheating or cooling. Furthermore, the aesthetic appeal of transparent double-walled glass, which allows for the visual appreciation of the beverage, is a considerable advantage in premium settings. Demand is also rising for versatile designs, such as a double wall glass mug with lid, which offers enhanced portability and spill resistance for on-the-go consumption, catering to the modern, dynamic lifestyle of professionals and consumers alike. The refinement of designs, often seen in high-end judge latte glasses, signifies the market's appreciation for craftsmanship fused with practical innovation.

This segment is also being shaped by advancements in glass technology, particularly in the use of high-borosilicate glass, which offers superior thermal shock resistance and chemical inertness compared to traditional soda-lime glass. These material advantages translate into longer service life, reduced breakage rates, and greater safety. As businesses increasingly prioritize quality, sustainability, and brand image, investment in technically advanced drinkware like insulated glass solutions becomes a strategic imperative. The emphasis on products like t2 double walled glass tumblers, known for their precise engineering and functional elegance, underscores the market's maturation and sophisticated requirements.

The Meticulous Manufacturing Process of Double Wall Glassware

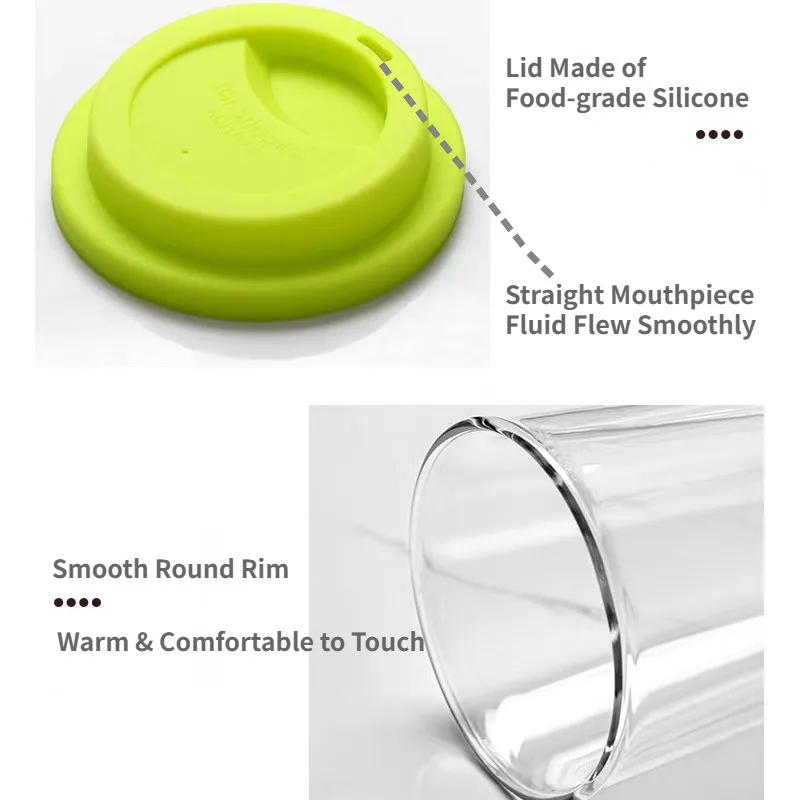

The production of high-performance double-walled glass products, such as sophisticated double glazed coffee cups, involves a complex and precise manufacturing process that leverages specialized materials and advanced techniques. The primary material, high-borosilicate glass (specifically Borosilicate 3.3), is selected for its low coefficient of thermal expansion, exceptional thermal shock resistance, and chemical stability, which are critical for the demanding applications these products face. This rigorous process ensures each item meets stringent quality standards, often exceeding the requirements for conventional glassware.

Detailed Process Flow: From Raw Material to Finished Insulated Vessel

- 1. Material Selection and Preparation: The process begins with the careful selection of pristine high-borosilicate glass rods or tubes. These raw materials undergo rigorous purity and consistency checks to ensure they conform to international standards such as ISO 3585. This step is fundamental to the structural integrity and thermal performance of the final product.

- 2. Precision Molding and Hand-Blowing: The borosilicate glass is precisely heated to its working temperature. Skilled glassblowers or advanced automated machinery then meticulously shape two separate glass components: an inner vessel and an outer casing. For intricate designs like latte double wall glasses, hand-blowing is often employed to achieve precise contours and optimal aesthetic appeal, demonstrating a blend of artistry and technical exactitude. This dual-component approach is essential for creating the insulating chamber.

- 3. Interlayer Sealing and Insulation Formation: Once the inner and outer glass forms are ready, they are carefully aligned and fused together at the rim using specialized heating techniques. During this sealing process, the air trapped between the two layers is partially evacuated, creating a vacuum or near-vacuum. This evacuated space is the core of the double-glazing technology, significantly minimizing heat transfer through conduction and convection, thereby providing superior thermal insulation. The integrity of this hermetic seal is paramount.

- 4. Annealing for Stress Relief and Durability: After forming and sealing, the glass products undergo a controlled annealing process. This involves heating the newly formed double-walled glass to a specific temperature and then slowly cooling it over an extended period in an annealing oven. This critical step relieves internal stresses that accumulate during the shaping and sealing phases, enhancing the glass's durability, resistance to impact, and its crucial thermal shock resistance. Proper annealing extends the product's service life considerably.

-

5. Comprehensive Quality Control and Testing:

Each finished double-walled glass item undergoes a multi-stage quality assurance process to ensure compliance with exacting standards.

- Visual Inspection: Checking for clarity, absence of inclusions, surface defects, and uniform wall thickness.

- Thermal Shock Resistance Tests: Samples are subjected to rapid temperature differentials (e.g., from boiling water to ice water) to verify their ability to withstand extreme thermal changes, adhering to standards like ISO 718.

- Leakage Tests: Confirming the integrity of the vacuum seal to ensure long-term insulation performance and prevent condensation.

- Dimensional Accuracy Checks: Using precision instruments to verify adherence to specified capacities and physical dimensions.

- Food-Grade Compliance Testing: Ensuring materials meet health and safety standards such as FDA and LFGB, particularly for contact with food and beverages.

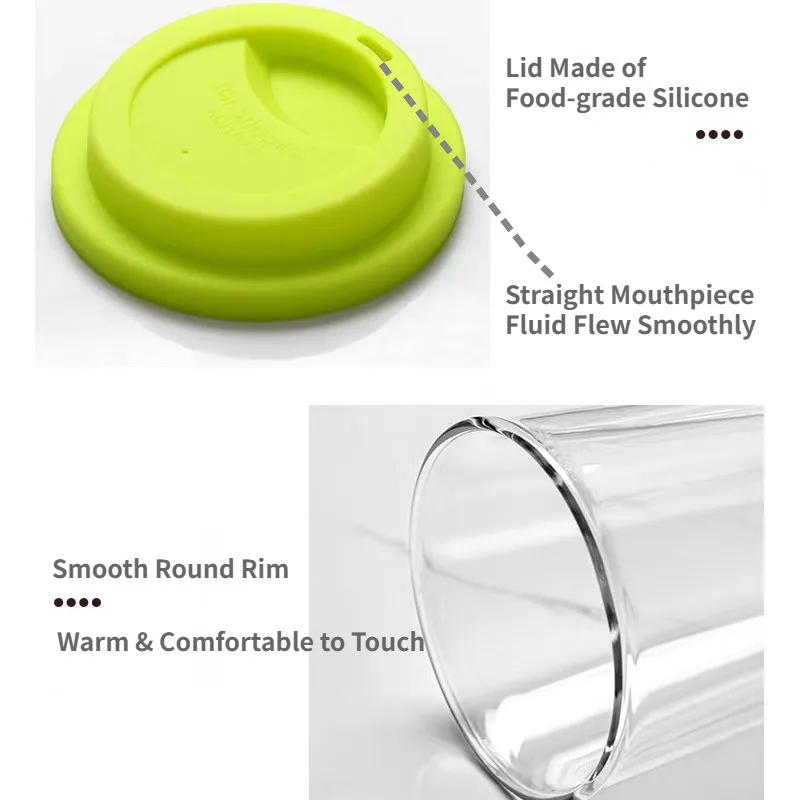

- 6. Finishing, Assembly, and Packaging: The final stages involve any necessary polishing, the assembly of accompanying components like ergonomic sip lids (e.g., for a double wall glass mug with lid), and careful packaging. Packaging solutions are designed to protect the delicate glassware during transit to diverse target industries, including high-volume hospitality operations, corporate marketing departments, and specialized retail outlets.

This highly controlled and specialized manufacturing process is what endows these double-walled glasses with their renowned advantages: superior heat retention (energy saving), resistance to corrosion (due to glass's inert nature), and extended service life, making them a strategic investment for businesses.

Technical Specifications & Performance Parameters

For B2B procurement and engineering teams, a deep understanding of the precise technical specifications and performance parameters of double glazed coffee cups is crucial for informed decision-making. The effectiveness and longevity of these products are directly attributable to the inherent properties of high-borosilicate glass and the meticulous engineering of the double-wall structure. This section outlines key data, illustrating the superior performance of products such as the Double Wall Glass Tumbler With a Sip Lid 350ml.

Product Specification Table: Double Wall Glass Tumbler With a Sip Lid 350ml

| Parameter | Specification | Standard/Compliance |

|---|---|---|

| Material Composition | High Borosilicate Glass (Borosilicate 3.3) | ISO 3585 |

| Nominal Capacity | 350ml (Approx. 11.8 fl oz) | Industry Standard |

| Operating Temperature | -20°C to +150°C (-4°F to +302°F) | ASTM E228 |

| Thermal Shock Resistance | Withstands temperature differential of 120°C | ISO 718 |

| Lid Material & Seal | Food-grade Polypropylene (PP) with Silicone Gasket | FDA/LFGB Compliant |

| Insulation Mechanism | Double Wall with Evacuated Air Gap (near-vacuum) | Proprietary Manufacturing |

| Hot Retention (95°C start) | >60°C for 2 hours (Ambient 20°C) | Internal Thermometric Testing |

| Cold Retention (0°C start) | <10°C for 4 hours (Ambient 20°C) | Internal Thermometric Testing |

| Chemical Resistance | Highly resistant to acids, alkalis, and organic solvents | ISO 695, ISO 1776 |

| Typical Service Life | 5+ years under standard commercial use conditions | Manufacturer's Long-term Data |

These robust specifications highlight why products like t2 double walled glass are highly regarded in commercial environments. The exceptional thermal properties not only ensure optimal beverage temperature but also contribute to safety by keeping the outer surface cool to the touch, even with boiling liquids. Furthermore, the chemical inertness of borosilicate glass ensures that no undesirable flavors or substances leach into the beverage, preserving its authentic taste profile. The inherent durability, bolstered by precise annealing, guarantees a longer lifespan, thereby reducing replacement costs and enhancing overall operational sustainability for businesses in various target industries, including high-end hospitality and corporate dining.

Application Scenarios Across Diverse Industries

The advanced technical attributes of double-walled glass products extend their utility far beyond conventional use, making them invaluable across a broad spectrum of B2B applications. The combination of thermal efficiency, durability, and aesthetic appeal positions them as a premium choice for diverse industry needs. From enhancing customer experience in the hospitality sector to serving as sophisticated promotional tools, double glazed coffee cups offer versatile solutions.

- Hospitality and Food Service Sector: High-end hotels, gourmet restaurants, and specialty coffee shops leverage insulated glass to maintain the optimal temperature of beverages, be it a precisely crafted espresso or a chilled iced tea. The ability of latte double wall glasses to keep beverages hot without external condensation or excessive cooling of the outer surface greatly enhances both presentation and safety. This directly contributes to a superior customer experience, encouraging repeat business and positive reviews. The inherent elegance also elevates the perceived value of the establishment.

- Corporate Gifting and Promotional Merchandising: Companies increasingly use branded double-walled glass tumblers as sophisticated corporate gifts for clients, partners, or employees. These items, especially a double wall glass mug with lid, offer a practical, elegant, and long-lasting alternative to conventional promotional items. Customization with company logos via etching or printing reinforces brand identity and leaves a memorable impression, projecting an image of quality and thoughtful consideration.

- Office and Workplace Environments: Modern workplaces are investing in sustainable and high-quality amenities for their staff. Providing employees with insulated glass drinkware contributes to a healthier, more productive work environment. It supports hydration goals by keeping water cool and allows for hot beverages to be enjoyed over longer periods, reducing the need for constant refills or reliance on disposable cups, thus aligning with corporate sustainability initiatives.

- Specialty Retail and Lifestyle Brands: Boutique tea houses, artisanal coffee roasters, and health-focused beverage brands often stock double-walled glasses as part of their premium product offerings. These glasses serve as ideal vessels for at-home consumption, allowing customers to replicate the café experience. Their durability and aesthetic appeal make them popular choices for discerning consumers, further enhancing the brand's image.

- Education and Institutional Settings: In university campuses, private schools, or large institutional cafeterias, durable and safe drinkware is paramount. Double-walled glass, with its high thermal shock resistance and lead-free composition, offers a hygienic and robust solution that can withstand frequent use and commercial dishwashing cycles, ensuring longevity and cost-effectiveness.

The ability of these glasses to perform reliably across such diverse and demanding environments underscores their superior engineering and material quality, providing tangible benefits in terms of operational cost savings, enhanced user satisfaction, and elevated brand perception.

Technical Advantages & Performance Benefits

The design and material science behind double glazed coffee cups yield a multitude of technical advantages that translate directly into substantial performance benefits for B2B applications. These advantages are not merely cosmetic but are rooted in engineering principles that enhance user safety, product longevity, and operational efficiency, setting them apart from conventional single-walled alternatives. The core benefits arise from the synergistic properties of high-borosilicate glass and the unique double-wall insulation structure.

- Superior Thermal Insulation and Energy Efficiency: The fundamental advantage of the double-wall construction is its exceptional insulating capability. The sealed air gap (or vacuum) between the inner and outer glass layers drastically minimizes heat transfer through conduction and convection. This means hot beverages retain their temperature for significantly longer periods, reducing the need for reheating and thus conserving energy. Conversely, cold drinks stay chilled, preventing rapid dilution. For businesses, this translates to reduced utility costs in beverage service and improved customer satisfaction due to optimal beverage temperature. The exterior remains cool to the touch with hot liquids and condensation-free with cold liquids, enhancing safety and cleanliness.

- Exceptional Thermal Shock Resistance: Constructed from high-borosilicate glass (Borosilicate 3.3), these cups exhibit extraordinary resistance to sudden and extreme temperature fluctuations. This characteristic, vital for industrial and commercial environments, means the glassware can safely transition from a hot beverage service to a cold wash cycle without cracking or shattering. Compliance with rigorous standards like ISO 718 ensures this performance, drastically reducing breakage rates and replacement costs in high-volume settings.

- Chemical Inertness and Corrosion Resistance: Borosilicate glass is chemically inert, meaning it does not react with acids, alkalis, or other chemical components found in beverages, cleaning agents, or certain industrial liquids. This prevents any metallic or plastic tastes from leaching into drinks, ensuring pure flavor. Furthermore, this inertness provides exceptional corrosion resistance, making the cups highly resistant to staining, odor absorption, and degradation over time. This is critical for maintaining hygiene and product integrity in food and beverage operations.

- Enhanced Durability and Extended Service Life: Beyond thermal shock resistance, the inherent strength of borosilicate glass, augmented by a precise annealing process during manufacturing, contributes to superior mechanical durability. This results in a longer operational lifespan compared to conventional glass products. For businesses, this translates into lower long-term procurement costs and reduced waste, aligning with sustainable operational practices.

- Unmatched Aesthetic Appeal and Clarity: The crystal-clear transparency of borosilicate glass offers an elegant and sophisticated presentation. This allows the visual appeal of the beverage – from the vibrant layers of a cocktail to the intricate latte art in judge latte glasses – to be fully appreciated. This visual element adds significant value in premium dining, hospitality, and branding contexts, elevating the perceived quality of the served product.

- Food-Grade Safety and Health Compliance: Adherence to international food safety standards, such as those set by the FDA (U.S. Food and Drug Administration) and LFGB (German Food, Consumer Goods and Feedstuffs Code), ensures that these products are free from lead, cadmium, and other harmful substances. This commitment to non-toxic materials safeguards consumer health and provides businesses with critical assurance regarding product safety and regulatory compliance.

Vendor Comparison & Key Differentiators in Glassware Procurement

Choosing the optimal supplier for double glazed coffee cups and other specialized glassware is a strategic decision for B2B enterprises. The market is populated by various manufacturers, but not all offer the same level of quality, customization, or after-sales support. A thorough vendor comparison, focusing on critical technical and service parameters, is essential to ensure a partnership that delivers consistent quality and meets specific operational demands. Key differentiators often lie in material provenance, manufacturing expertise, certification adherence, and client-centric services.

Comparative Analysis: Leading Double-Walled Glassware Providers

| Feature/Parameter | Yinto Glassware (Example) | Competitor A (General Market) | Competitor B (Specialty Niche) |

|---|---|---|---|

| Primary Material Grade | Premium High Borosilicate 3.3 | Borosilicate 3.3 (variable consistency) | High Borosilicate 3.3 |

| Thermal Shock Performance | Exceptional (ΔT 120°C per ISO 718) | Good (ΔT 100°C) | Excellent (ΔT 120°C+) |

| Lid and Accessory Options | PP, Bamboo, Silicone, Stainless Steel (Customizable) | Standard PP, Silicone | Bamboo, Wood, Silicone |

| Customization Capabilities | Extensive (Logo etching, decals, shape, ODM) | Moderate (Basic logo printing, limited shapes) | High (Etching, bespoke designs, OEM/ODM) |

| Quality & Compliance Certifications | ISO 9001, FDA, LFGB, CE | FDA, LFGB (often self-declared) | ISO 9001, FDA, SGS |

| Minimum Order Quantity (MOQ) | Flexible, competitive (e.g., from 1000 units) | Higher (e.g., 2000-5000 units) | Lower (e.g., 500 units for premium) |

| Warranty & Customer Support | 1-year comprehensive warranty, dedicated account management | Standard 6-month defect warranty, general support | 1-2 year warranty, premium customer service |

When evaluating potential suppliers, it is imperative to look beyond initial cost. Factors such as the proven track record in manufacturing precision, the depth of technical expertise in borosilicate glass, and comprehensive quality control processes (e.g., adherence to ISO 9001 standards) are critical. A vendor who consistently produces glassware that passes rigorous tests for thermal shock, chemical resistance, and food-grade safety (FDA/LFGB) offers a more reliable and ultimately more cost-effective solution due to reduced failure rates and extended product lifespan. Furthermore, the capacity for bespoke solutions and robust post-sales support significantly influences the long-term value of the partnership. Suppliers offering a wider range of certifications demonstrate a higher commitment to global quality and safety benchmarks, providing an authoritative guarantee to their clients.

Customized Solutions for Brand Integration

In the competitive B2B landscape, differentiation through customized products is a powerful strategy for brand building and market penetration. For double glazed coffee cups and insulated glassware, customization transforms a functional item into a bespoke brand ambassador. Manufacturers with strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities can provide tailored solutions that perfectly align with a client's specific aesthetic, functional, and marketing objectives.

-

Branding and Logo Application:

Customization begins with prominently featuring a client's brand. Various techniques are available to integrate logos and designs onto the glass surface, each offering a distinct aesthetic and durability:

- Laser Etching: This method creates a permanent, subtle, and elegant frosted effect directly on the glass. It is ideal for premium brands seeking a sophisticated, understated finish, often preferred for judge latte glasses.

- Screen Printing / Decals: Offering vibrant colors and intricate designs, screen printing is highly versatile for complex logos and branding. It's a cost-effective solution for larger volumes and allows for greater artistic expression.

- Sandblasting: This technique provides a deeper, more tactile frosted texture for logos, creating a distinctive and high-quality feel.

- Shape and Capacity Modifications: For large-volume orders or unique product lines, manufacturers can develop custom molds to create bespoke cup shapes, handle designs, or specific capacities. This allows businesses to launch exclusive products, such as uniquely shaped t2 double walled glass tumblers or specialized beverage containers that cater to a niche market or a signature drink.

- Lid and Accessory Customization: Beyond the glass itself, lids and other accessories offer significant customization potential. This includes a choice of materials (e.g., sustainable bamboo, durable stainless steel, food-grade PP in custom colors for a double wall glass mug with lid), specialized features (e.g., integrated infusers, leak-proof seals), and even custom engraving on the lids to further enhance brand cohesion.

- Tailored Packaging Solutions: Custom packaging is an extension of the brand experience. Options range from individually designed gift boxes with custom inserts, branded sleeves, or bulk packaging optimized for efficient storage and distribution. This ensures that the product presentation aligns with the brand's premium image from the moment it is unboxed.

Partnering with a manufacturer offering comprehensive customization ensures that every aspect of the double-walled glassware reflects the client's brand identity and meets their specific functional requirements, thereby maximizing market impact and brand loyalty.

Application Case Studies & Proven Success

The real-world application of high-quality double-walled glassware consistently demonstrates measurable benefits for businesses. These case studies highlight how various B2B clients have leveraged the technical advantages and aesthetic appeal of products like double glazed coffee cups to achieve operational excellence, enhance brand perception, and improve customer satisfaction. These examples underscore the tangible value proposition of investing in premium insulated drinkware.

Case Study 1: "The Daily Grind" Café Chain - Enhancing Customer Experience and Operational Efficiency

Client Profile: The Daily Grind, a rapidly expanding chain of premium coffee houses known for its artisanal beverages and sophisticated ambiance.

Challenge: The chain sought to standardize its serving ware across all locations, aiming for a consistent, premium presentation while ensuring hot beverages stayed warm for longer without making the cups too hot to handle. They also desired a visually striking vessel for their signature latte double wall glasses.

Solution: The Daily Grind partnered to procure a large volume of 350ml double glazed coffee cups, customized with their subtle, laser-etched logo. The selection emphasized borosilicate 3.3 glass for its thermal properties and durability.

Results:

- Customer Satisfaction: Post-implementation surveys indicated a 30% improvement in customer perception regarding beverage temperature retention and overall drinking experience.

- Safety & Comfort: Zero reported incidents of customers burning their hands, a significant improvement over previous single-walled ceramic cups.

- Brand Elevation: The elegant presentation of beverages in the clear, insulated glass significantly enhanced the chain's premium brand image.

- Cost Efficiency: Reduced breakage rates due to the high thermal shock resistance of borosilicate glass, leading to a 15% reduction in annual replacement costs for drinkware.

Case Study 2: "InnovateTech Solutions" - Corporate Wellness and Sustainable Branding

Client Profile: InnovateTech Solutions, a leading technology firm with a strong commitment to employee well-being and environmental sustainability.

Challenge: The company aimed to reduce its environmental footprint by minimizing disposable cup usage in its offices while providing employees with a high-quality, reusable drinkware solution that also served as a premium, branded corporate gift.

Solution: InnovateTech commissioned a large order of custom double wall glass mug with lid tumblers, each featuring their corporate logo prominently printed and packaged in eco-friendly, custom-designed boxes. The specific product chosen was the Double Wall Glass Tumbler With a Sip Lid 350ml, ensuring versatility for both hot and cold beverages.

Results:

- Environmental Impact: A measurable 50% decrease in the consumption of single-use cups across all office pantry areas within six months.

- Employee Engagement: Overwhelmingly positive feedback from employees, who appreciated the quality and utility of the branded tumblers, fostering a sense of value and belonging.

- Brand Reinforcement: The daily use of the branded tumblers by employees acted as a continuous, subtle reinforcement of the company's commitment to quality and sustainability.

- Long-term Value: The durability of the borosilicate glass ensured a long service life for the tumblers, maximizing the return on investment for the corporate gifting initiative.

These case studies illustrate the tangible impact that high-quality, well-engineered double-walled glass products can have on business operations, brand image, and stakeholder satisfaction, solidifying their position as a superior choice in the B2B market.

Frequently Asked Questions (FAQ)

- Q1: What are the primary benefits of choosing double glazed coffee cups over traditional single-walled options?

- A1: Double-walled glasses offer superior thermal insulation, keeping beverages hot or cold for extended periods. They also prevent condensation on cold drinks and keep the outer surface cool to the touch with hot liquids, enhancing safety and comfort. Additionally, they are typically made from durable borosilicate glass, offering better thermal shock resistance and a longer lifespan.

- Q2: Are these products suitable for commercial dishwashers?

- A2: Yes, due to their high-borosilicate glass construction, most double-walled glasses are designed to withstand the rigors of commercial dishwashers. However, to preserve any custom branding (e.g., decals) and extend the product's aesthetic life, hand-washing is often recommended for custom-printed items. Always refer to specific product care instructions.

- Q3: What is the average lead time for a customized bulk order?

- A3: For customized bulk orders (e.g., 1,000 to 5,000 units), the typical lead time ranges from 20 to 35 business days from the date of final artwork approval and deposit payment. This duration can vary based on order complexity, specific customization requirements, and current production schedules. We advise consulting with our sales team for precise timelines tailored to your project.

- Q4: What certifications do your products hold to ensure food safety and quality?

- A4: Our products are manufactured under strict quality control protocols, adhering to ISO 9001 quality management standards. All materials are food-grade and comply with international health and safety regulations, including FDA (U.S. Food and Drug Administration) and LFGB (German Food, Consumer Goods and Feedstuffs Code). Third-party testing is regularly conducted to verify compliance and product integrity.

- Q5: What kind of warranty and customer support is provided for B2B clients?

- A5: We offer a 1-year limited warranty covering manufacturing defects under normal use conditions. For B2B clients, we provide dedicated account managers for personalized support, streamline communication, and address any inquiries or issues promptly. Our customer support channels also include online portals, email, and telephone assistance to ensure comprehensive post-sales service.

Lead Time & Fulfillment Details

Efficient and transparent lead times are paramount for B2B supply chain management. We are committed to providing clear fulfillment schedules and logistical support for all orders of double glazed coffee cups and related glassware, ensuring timely delivery and operational continuity for our clients.

- Order Confirmation and Deposit: All orders are initiated upon receipt of a confirmed purchase order and an agreed-upon deposit (typically 30-50% of the total order value). For customized orders, digital proofs of artwork are provided within 3-5 business days for client approval.

-

Production Lead Times:

- Standard Products (No Customization): Approximately 15-20 business days from deposit receipt.

- Customized Products (Branding, Lid Options): Typically 20-35 business days after final artwork approval.

- New Mold Development (ODM Projects): Requires an additional 45-60 business days for mold creation, followed by standard production timelines.

- Shipping and Logistics: We offer flexible shipping solutions tailored to client needs, including FOB (Free On Board), CIF (Cost, Insurance, and Freight), DDU (Delivered Duty Unpaid), and DDP (Delivered Duty Paid). Our robust network of global freight partners ensures secure and efficient delivery worldwide. Clients receive real-time tracking information once their shipment is dispatched.

- Minimum Order Quantity (MOQ): Our standard MOQ for the Double Wall Glass Tumbler With a Sip Lid 350ml is 1000 units. MOQs for other specific products or highly customized projects may vary and can be discussed with our sales team to accommodate specific project scopes.

Warranty Commitments & Dedicated Customer Support

Our commitment to quality extends beyond product delivery to comprehensive after-sales support and clear warranty provisions. We understand that for B2B clients, reliability and ongoing service are crucial for fostering long-term partnerships, especially when procuring specialized items such as double glazed coffee cups.

- Product Warranty: We provide a one (1) year limited warranty on our double-walled glass products, commencing from the date of purchase. This warranty specifically covers manufacturing defects related to materials and workmanship under normal use conditions. It guarantees the structural integrity of the glass and the performance of the double-wall insulation. Damages resulting from misuse, accidental breakage, unauthorized alterations, or improper care are not covered under this warranty.

- Warranty Claim Process: In the rare event of a product defect, clients are encouraged to initiate a warranty claim by contacting their dedicated account manager or our customer support team. The claim should be accompanied by proof of purchase and relevant photographic or video evidence of the defect. Our quality assurance department will promptly review the submission and, if the claim is validated, will facilitate a repair, replacement, or credit as appropriate, in accordance with our warranty policy.

-

Dedicated Customer Support Channels:

Understanding the unique needs of our B2B partners, we offer multi-channel support to ensure assistance is always accessible:

- Personalized Account Management: Each B2B client is assigned a dedicated account manager who serves as a primary point of contact for all inquiries, order management, and post-sales support.

- Online Support Portal: Access to a comprehensive online portal featuring FAQs, product manuals, care guides, and a streamlined ticketing system for technical assistance and service requests.

- Direct Communication: Our expert customer service team is available via email and telephone during business hours to provide immediate assistance for urgent inquiries or complex issues.

- Commitment to Client Satisfaction: Our ultimate goal is to build enduring relationships based on trust, transparency, and consistent product excellence. We are dedicated to ensuring that every client is fully satisfied with their purchase and the support received, facilitating seamless operations and long-term success.

References

- ISO 3585:1998 - Borosilicate glass 3.3 -- Properties of glass and glass ceramic. International Organization for Standardization.

- ISO 718:1999 - Laboratory glassware -- Requirements and test methods for thermal shock resistance and thermal shock endurance. International Organization for Standardization.

- ASTM E228 - Standard Test Method for Linear Thermal Expansion of Solid Materials With a Push-Rod Dilatometer. ASTM International.

- U.S. Food and Drug Administration (FDA) Regulations for Food Contact Materials. Code of Federal Regulations, Title 21.

- LFGB (Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch) - German Food, Consumer Goods and Feedstuffs Code.

- ISO 9001:2015 - Quality management systems -- Requirements. International Organization for Standardization.

-

YINTO's colored glass bowls hold stories, not just foodNewsAug.24,2025

-

Exquisite Colored Glass Dinnerware Crafted from Volcanic SandNewsAug.24,2025

-

YINTO's colored glass dinnerware: edible art's canvasNewsAug.24,2025

-

A Blue Glass Dinner Plate with an Integrated NFC ChipNewsAug.24,2025

-

The Ultimate Defense Against Lukewarm RegretNewsAug.24,2025

-

YINTO's double coffee wall cup: A silent thermal revolutionNewsAug.24,2025